Weighbridge installation and upgrade at Mid Hants quarry, Fawley.

At Griffith Elder we work with many different businesses across a wide variety of sectors, not just agriculture. We’ve also supplied weighbridges for logistics, road authorities and mining and quarrying industries. The latter is a key industry. They not only require highly accurate scales, but they also need to be highly robust to deal with the weight of such heavy vehicles and abrasive materials.

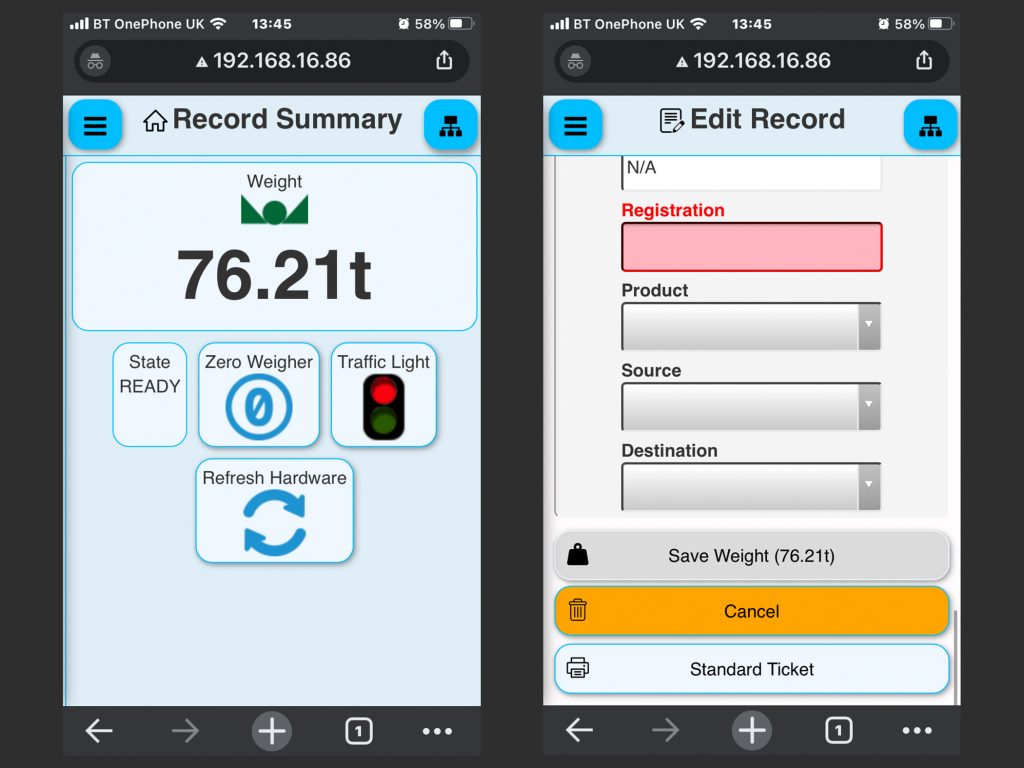

Along with our full-size weighbridges, our software team have developed the Weighbus software in-house. It is therefore purpose-built, making the weighing process efficient. These products have been supplied by ourselves at Griffith Elder to Mid Hants at their Fawley quarry in Hampshire.

Mid Hands Installation

Mid Hants supply to a wide variety of customers within the construction, equestrian and sports sectors. They supply these sectors with a range of materials from their quarries. This can include materials from larger rocks to sands for various purposes.

Mid Hants required a new full size weighbridge (as seen above) that is robust enough for their fleet of dumpers. The new full size weighbridge has a 12mm chequer plate. This allows it to withstand the abrasiveness of the materials that build up on the site. We manufacture our weighbridges at our own factory in Bury St Edmunds, making this a simple upgrade whilst maintaining a good manufacture time.

The weighbridge is also 15.3m long by 3.5m wide. The 3.5m width allows for Mid Hants to easily weigh the wider vehicles. This is also one of our standard sizes that we offer. Mid Hants was additionally the first site to have a new weighbridge installed with the Weighbus software.

Along with the new weighbridge, Mid Hants also required a variety of extras, these included:

- Cameras

- Traffic lights

- Large displays

- Fobs & fob reader

Used by the fleet for efficient weighing without the need to leave the vehicle

An existing weighbridge, used for customers that are collecting sands and aggregates, was also upgraded with a new indicator along with the Weighbus software. Both weighbridges are running on the same software. This therefore allows the whole site to share the same database, whether using fobs by a company driver, or manually operating the customer weighbridge.

Weighbus Software Features

- Ability to create multiple types of tickets.

This flexibility allows different types of data to be captured. For example at Mid Hants, they collect data for both incoming quarry materials as well as weighing outgoing materials for customers. - Connectivity to ANY device on the same network.

Any device be it mobile phone, tablet or computer can connect to the Weighbus software. Use it just like being in the office. - Driver remote buttons – Read and capture data in one press of a button.

Data captured without leaving the vehicle, speeding up weighing and eliminating mistakes, making for a more efficient process.

- Security and Privacy.

All user operations are controlled via user logins. Assign users to user groups and define their permissions by management. - Flexible data reports.

User configured reports are created with specific filters to create CSV files, including only the data needed. Run reports run on a schedule and import onto other software.

These software features, allow companies like Mid Hants to use their weighbridge(s) for multiple purposes without complications or slowing down business.

Contact us today for more information on our Weighbus software and how it can help optimise your weighing process!

Full Size Weighbridge, Installations, Quarries, Scales, Truck Scales, United Kingdom, Weighbridges