Home » Industrial Weighing Products » Weighbridges » Multi-Axle Weighbridge

Multi-Axle Weighbridge

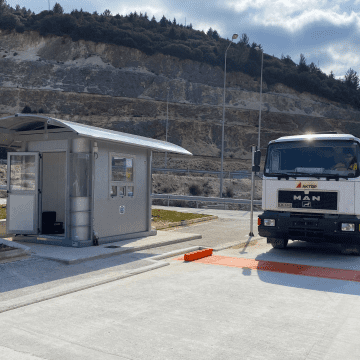

The Griffith Elder Multi-Axle Weighbridge is an affordable and space-efficient alternative to a Full Sized Weighbridge. Weigh any vehicle regardless of its length or number of axles. The Ton-Tel™ Split-Weigh system automatically captures axle weights and adds them together to ensure efficient and accurate weighings are achieved.

- Features

Multi-Axle Weighbridge Features:

- Typical platform sizes: 6.0 metres long by 3.0 metres wide, 6.3 metres long by 3.5metres wide, 7.8 metres long by 3.0 metres wide

- Maximum weight on platform up to 100 tonnes

- Welded steel superstructure with a durbar surface plate for maximum strength

- Split-weighing for maximum accuracy

- Accuracy +/- 1%

- Axle-group load control

- Quick and easy installation and use

- Load cells chosen to match capacity of weighbridge

- Power source 110/220V ac; 50/60 hz. Can also be run from 12 volts DC or solar panel. You can also add leisure batteries

- Installation-Plug and Weigh™

The Multi-Axle weighbridge is designed with Plug and Weigh™ technology and factory calibrated Weightel™ digital load cells. There is minimal set-up time on site, requiring no special tools to install the weighbridge system. The Multi-Axle arrives ready to be installed into a pre-prepared pit. Framework is also provided to ensure that the weighbridge can be pit-mounted with ease. The load cells have been sealed against the elements to IP68 to ensure a long and trouble free life. A signal cable runs from the weighbridge to the indicator and another runs from the indicator to the large display with integrated traffic light. Once these cables are plugged in the system is ready to be used.

- Operation-Plug and Weigh™

The Multi-Axle weighbridge is a complete kit weighbridge system, the price includes a large display integrated with traffic light and tripod or wall mount bracket. The price also includes a weatherproof peliTM case, this houses the indicator, tally-roll printer and USB port. The Multi-Axle kit is ideal for rugged outdoor use. It is perfect for remote sites running from either 12V mains power or leisure batteries. (Desktop versions of the indicator are also available).

The traffic light guides vehicles onto the Multi-Axle weighbridge. The green arrow/red cross system shows the driver when to move onto the weighbridge and when to stop to allow the weighbridge to stabilize and capture the axle weights. The traffic light will then inform the driver to move forward to either weigh the next set of axles, or the vehicle can move off the weighbridge. Small vehicles can be weighed in one part, tractors and trailers can be weighed in two parts, whilst larger vehicles such as articulated lorries are weighed in three parts. The Ton-Tel Split Weigh system uses a well-established method of split-weighing axle groups to weigh the vehicle.

As the vehicle moves over the weighbridge, the weight of each group of axles is automatically captured in just three seconds, allowing for a time efficient weighing. Once weighing is complete, the individual weights are automatically added together to give the total weight of the vehicle. The in-built printer in the peliTM case will then automatically print this information. The desk tally roll printer will automatically print the weights for desk mounted indicators. The data is also automatically saved as a single line CSV file on the USB stick, this data can then be transferred to an Excel spreadsheet. This allows for paper and electronic copies of weight records. If only electronic copies are required, the printer can be turned off.

- The Importance of Civil Works

There are two essential rules for obtaining accurate weights when split weighing a vehicle. Firstly, the weighing platform must be recessed into the ground at a prepared site. Secondly, the approach and exit to the weighing platform need to be level for approximately the length of the longest vehicle that is to be weighed. Typically the concrete approach and exit should each be 10 metres long, allowing the weighing of vehicles in both directions.

The pit frame supplied ensures the weighbridge is located correctly and simplifies construction. Griffith Elder recognise that the site of a weighbridge is of prime consideration, therefore we offer an advisory service for location. We additionally provide easy-to-follow instructions and technical assistance. Our civil engineering team are able to provide a complete turn-key package if required. Griffith Elder provides support in all aspects of installation and commissioning.

- Easy to Install - S Type Load Cells

The Multi-Axle Weighbridge is factory calibrated, so on-site installation is very easy. The weighbridge is ready to install into a pre-prepared pit. Using a Griffith Elder pit frame simplifies construction and ensures that the weighbridge is located correctly.

- Recording Options

A large external LED display is available for quick and easy viewing of the weights. Using a traffic light in conjunction with the large display informs the driver when to move on and off the weighbridge. The Ton-Tel™ Software Range is compatible with the weighbridge.

- Weighbridge How To's: Using a Multi Axle Weighbridge

This video will give you a short overview of how to use a Multi Axle weighbridge to weigh a tractor and trailer.

Find out more about our Multi-Axle Weighbridge

Contact us on: +44 (0)1284 719619 or sales@griffith-elder.com to find out more information about the Griffith Elder Multi-Axle Weighbridge

Contact Price