5 Weighbridge Solutions for Quarry Operations: A Buyer’s Guide

Weighbridges are essential tools for quarry operations, helping to measure and manage material movement efficiently. This guide will help you understand the best weighbridge solutions for your quarry, focusing on accuracy, durability, and advanced features. We’ll explore various types of weighbridges, their uses in quarries, and key things to think about when choosing one.

Key Takeaways

- Weighbridges are crucial for accurate material measurement and efficient quarry management

- Various types of weighbridges are available, including full-length, axle, and portable options

- Consider factors such as weighing capacity, durability, integration capabilities, and maintenance requirements

- Installation and setup processes are critical for optimal weighbridge performance

- Regular maintenance and calibration ensure longevity and accuracy of weighbridge systems

- Weighbridges often provide a strong return on investment through improved efficiency and inventory control

- Compliance with legal and regulatory requirements is essential for weighbridge operations

Understanding Weighbridge Technology for Quarries

Weighbridges come in different types, each good for different quarry needs. Knowing these options helps you pick the best one for your operation. Let’s look at some common options and how they’re used in quarries:

1. Full-length weighbridges: These can weigh entire vehicles at once, ideal for large quarry trucks. They give the most complete weight measurement for heavy-duty vehicles often used in quarrying. They’re very accurate and efficient, allowing trucks to be weighed quickly in busy quarries.

2. Axle weighers: These weigh one axle at a time, useful for checking if trucks are overloaded on specific axles. They’re really good for making sure trucks follow road rules and don’t have too much weight on one part of the vehicle, which could cause damage or be unsafe.

3. Portable weighbridges: Great for temporary sites or when you need to move your weighing system. They’re perfect for quarries that change their layout often or have multiple digging sites. You can quickly set them up and move them as needed, which is great for quarries that are always changing.

5 Weighbridge Solutions for Quarry Operations

1. Griffith Elder Ton-Tel™ Full Size Portable Weighbridge

This portable full-size weighbridge is perfect for quarries that need flexibility. It’s easy to move and set up, making it ideal for temporary sites or changing quarry layouts. The Ton-Tel™ system works well in tough quarry conditions, giving accurate measurements even when things get rough.

Key features:

- Lengths from 4 to 32 meters, fitting many different vehicle sizes

- Widths of 3.0, 3.5, and 4.0 meters available, good for various truck types

- Made of strong welded steel to last in tough quarry conditions

- Comes with Plug and Weigh™ software for easy setup and use with other systems

- Handles dust, shaking, and temperature changes common in quarries

- Modular design for easy moving and quick setup

2. Griffith Elder Single Axle Weighbridge

The Griffith Elder Single Axle Weighbridge is great for quarries that need to check individual axle weights. This is important for making sure trucks aren’t too heavy on any one axle, which is crucial for road safety and following transportation rules. It’s a cost-effective solution for quarries that don’t need full-length weighbridges but still want accurate weight measurements.

Key features:

- 3.5 m x 0.85 m size, good for standard axle setups

- Can weigh up to 30 tonnes per axle, suitable for heavy quarry vehicles

- Weighs trucks while they’re moving for faster operation

- Automatically spots overweight axles, improving safety and rule-following

- Compact design needs little space, good for quarries with limited area

- Strong construction handles frequent use and tough quarry conditions

3. Griffith Elder Portable Single Axle Weighbridge

This portable single axle weighbridge combines the benefits of being movable with precise axle weighing. It’s perfect for quarries that need to move their weighing system often or have limited space. The system’s flexibility allows for quick setup at different spots within the quarry or even at multiple sites, making operations more efficient.

Key features:

- 2.5 meters wide, fitting a variety of truck sizes

- Can weigh up to 20 tonnes per axle, good for most quarry vehicles

- Only 300kg – easy to move with a forklift, great for moving around the quarry

- No special site preparation needed, saving time and money on setup

- Tough construction handles frequent moving and harsh quarry environments

- Comes with software for easy data management and reporting

4. Griffith Elder Multi-Axle Weighbridge

The Griffith Elder Multi-Axle Weighbridge is a great choice for quarries that need to weigh large trucks quickly and accurately. It can weigh multiple axles at once, saving time and improving efficiency. This system is particularly good for busy quarries where weighing trucks fast is important.

Key features:

- Available in lengths from 6.0 to 7.8 meters, fitting various truck types

- Widths of 3.0 to 3.5 meters, good for wide loads

- Can handle up to 100 tonnes, perfect for the heaviest quarry vehicles

- Uses Ton-Tel™ Split-Weigh system for accurate measurements of different axle groups

- Fast weighing reduces waiting times and makes operations more efficient

- Strong construction designed to last with constant use in tough quarry conditions

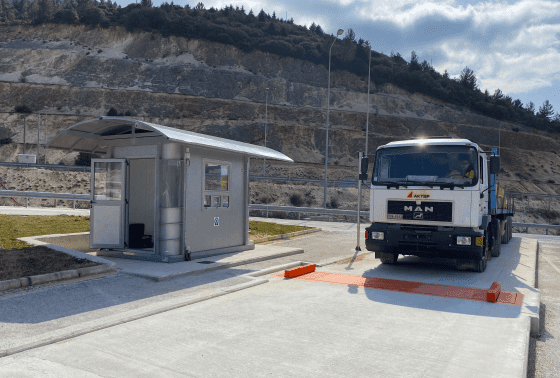

5. Fixed Full Size Weighbridge

Fixed full size weighbridges are the workhorses of many quarries. They’re built to last and can handle the heaviest loads day after day. While not movable, they offer the highest capacity and are ideal for busy quarries with a stable layout. These weighbridges provide a permanent solution for high-volume operations where reliability and durability are really important.

Key features:

- Permanent installation for long-term use, providing a stable weighing platform

- Highest weight capacity, often over 100 tonnes

- Can be connected with quarry management systems for smoother operations

- Often includes features like traffic lights better safety and efficiency

- Tough construction lasts for years of heavy use in harsh quarry conditions

- Usually offers the highest accuracy levels for precise material management

Portable Weigh Beams

When exploring weighbridge solutions for quarry operations, portable options offer unique advantages that complement traditional fixed systems. The Griffith Elder Portable Weigh Beams represent one such solution, providing the flexibility and mobility that modern quarry operations often require while maintaining the high precision necessary for accurate material management. These weigh beams particularly shine in scenarios where permanent installations may be impractical or when additional weighing capacity is needed across different locations within the quarry.

The Griffith Elder Portable Weigh Beams represent a revolutionary advancement in vehicle weighing technology, offering a lightweight and versatile alternative to traditional full-size portable weighbridges. Specifically engineered for agricultural and industrial applications, these weigh beams excel in both on and off-road conditions, making them ideal for farm use, construction sites, and remote locations. The system combines precision engineering with practical functionality, featuring the innovative Ton-Tel™ Split Weigh system that ensures maximum accuracy in every measurement. Whether weighing tractors, trailers, or standard UK articulated vehicles, this portable solution delivers professional-grade results while maintaining the flexibility to be easily transported and set up wherever needed. The complete system comes with essential peripherals and requires minimal setup time, allowing for immediate operation upon delivery.

Key Features

- Size Options: Available in 2.8m or 4.4m lengths

- Capacity: Maximum weight capacity of 60 tonnes

- Accuracy: Ton-Tel™ Split Weigh system for precise measurements

- Portability: Easily movable using a telehandler

- Power: 12V DC operation with 7-hour battery life

- Warranty: 2-year comprehensive coverage

Complete Package Includes:

- Traffic light system

- Large display screen

- Built-in printer

- USB data storage

Key Benefits

- Quick Setup: Factory calibrated – no special on-site setup required

- Fast Operation: Complete weighing process in under 20 seconds

- Automatic Recording: Weights automatically saved and printed

- Versatile Use: Suitable for farm use and remote locations

Optional Features

- Fob system for automatic net weight allocation

- Weatherproof carry case

- Desk mounting options available

Factors to Consider When Choosing a Weighbridge for Your Quarry

When picking a weighbridge for your quarry, there are several important things to think about. These factors will affect not only how well your weighbridge works at first but also how valuable it is to your operation in the long run:

Key Factors in Choosing a Quarry Weighbridge

- Weighing capacity and accuracy: Make sure the system can handle your heaviest loads precisely

- Durability in harsh environments: Quarries are tough on equipment, so choose a strong solution

- Integration with existing systems: Look for compatibility with your current software and processes

- Maintenance requirements: Think about long-term upkeep needs and costs

- Site layout and space constraints: The weighbridge should fit well into your quarry layout

- Total cost of ownership: Consider initial costs, maintenance, and potential efficiency gains

- Environmental factors: Think about dust, shaking, and extreme temperatures in your quarry

- Regulatory compliance: Make sure the weighbridge meets all relevant legal standards

- Scalability: Choose a solution that can grow with your quarry’s needs

- Support and service availability: Look for reliable after-sales support and quick service response

Installation and Setup of Weighbridges in Quarry Environments

Setting up a weighbridge in a quarry takes careful planning and execution. The installation process is crucial for ensuring the long-term accuracy and reliability of your weighing system. Here are some key steps and things to consider:

- Choose a level site with good drainage: This is crucial for keeping the weighbridge accurate and preventing water damage. The site should be stable and able to support the weight of both the weighbridge and the heaviest vehicles you’ll be weighing.

- Prepare the foundation according to manufacturer specifications: This may involve digging, concrete work, and reinforcement. The foundation is critical for keeping the weighbridge stable and making it last longer.

- Ensure proper power and data connections are available: Modern weighbridges often need reliable electrical supply and data connectivity to work well and connect with management systems.

- Follow all local regulations for weighbridge installation: This may include getting permits, following zoning laws, and meeting specific safety standards.

- Calibrate the weighbridge after installation: This ensures accuracy from day one and should be done by certified professionals.

- Install necessary extras: This might include traffic lights, or CCTV systems for monitoring.

- Conduct thorough testing: Run multiple test weighings with various vehicle types to ensure consistent accuracy across different loads.

- Train operators and staff: Proper training is essential for efficient operation and maintenance of the weighbridge system.

Maintenance and Longevity of Quarry Weighbridges

To keep your weighbridge working well for a long time, regular maintenance is key. A well-maintained weighbridge not only ensures accurate measurements but also makes the system last longer, giving you better value for your money. Here are some important maintenance tips and things to think about:

- Clean the weighbridge deck regularly to remove dirt and debris: This prevents buildup that can affect accuracy and damage parts. Use appropriate cleaning methods that won’t harm the weighbridge surface or electronics.

- Check load cells and cables for damage: These are critical parts that can affect weighing accuracy. Look for signs of wear, rust, or physical damage.

- Calibrate the weighbridge regularly, following manufacturer guidelines: This ensures continued accuracy. How often you need to calibrate may depend on how much you use it and local rules.

- Keep drainage systems clear to prevent water damage: Water buildup can lead to rust and electrical problems. Make sure all drainage channels and sumps are free from blockages.

- Train operators on proper use to prevent accidental damage: Using the weighbridge correctly helps it last longer. This includes placing vehicles correctly and controlling their speed.

- Conduct regular inspections of structural components: Look for signs of wear, rust, or damage to the weighbridge deck, ramps, and support structures.

- Maintain electronic components: Keep indicator displays, junction boxes, and other electronic parts clean and protected from the elements.

- Schedule professional maintenance: Have certified technicians perform thorough checks and maintenance at least once a year or as recommended by the manufacturer.

- Keep detailed maintenance records: This helps track how the weighbridge performs over time and can be useful for troubleshooting and warranty purposes.

- Update software regularly: If your weighbridge system includes software, make sure it’s kept up to date with the latest versions for best performance and security.

Legal and Regulatory Compliance

Weighbridges used for trade must meet certain legal requirements. Following the rules is not just about avoiding fines; it’s about ensuring fair trade practices and maintaining the reputation of your quarry operation. Here are some key points to consider regarding legal and regulatory compliance:

- Weighbridges must be certified and regularly checked by approved authorities: This typically involves initial verification and subsequent re-verifications at specified intervals.

- Operators may need special training or certification: This ensures that the weighbridge is used correctly and that weight tickets are issued properly.

- Records of weighings may need to be kept for a certain period: This is often required for auditing purposes and to resolve any disputes.

- There may be specific rules about how weights are displayed and recorded: This includes the units of measurement, precision of readings, and format of weight tickets.

- Compliance with local trade measurement laws: These can vary by region and may cover aspects such as maximum permissible errors in weighing.

- Environmental regulations: Some areas may have specific requirements for weighbridge installations to minimize environmental impact.

- Safety standards: Weighbridges must meet safety requirements for both operators and vehicle drivers.

- Data protection regulations: If the weighbridge system collects and stores customer data, it must comply with relevant data protection laws.

Always check your local laws and regulations to make sure your weighbridge operation is compliant. It’s a good idea to talk to legal experts or industry associations to stay updated on the latest requirements. Regular audits and compliance checks can help ensure that your weighbridge operation stays within legal boundaries.

Conclusion: Making an Informed Decision for Your Quarry’s Weighing Needs

Choosing the right weighbridge for your quarry is an important decision that affects your efficiency, accuracy, and bottom line. By carefully thinking about the factors we’ve discussed and understanding the various options available, you can select a weighbridge solution that will serve your quarry well for years to come.

Remember, the right weighbridge isn’t just about weighing trucks – it’s about improving your entire operation. A well-chosen weighbridge can make your processes smoother, improve accuracy, ensure you follow the rules, and ultimately help make your quarry more profitable. Think about both your current needs and future growth plans when making your decision.

For more information on weighbridge solutions for your quarry, don’t hesitate to contact weighbridge experts who can give you personalized advice based on your specific needs. With the right weighbridge in place, you’ll be well-equipped to manage your quarry’s material flow efficiently and accurately, setting your operation up for long-term success in a competitive industry.