Full Size Weighbridge Installation at a Quarry in Suriname

Griffith Elder has 30+ years’ of experience exporting, providing full support and guidance both in-country and remotely, which has proved particularly useful for our overseas customers.

This ensures a smooth installation, resulting in efficient operation of the weighbridge and reduced maintenance due to real site conditions being taken into consideration. Our aim is to provide a technical weighing system but make it simple for our customers.

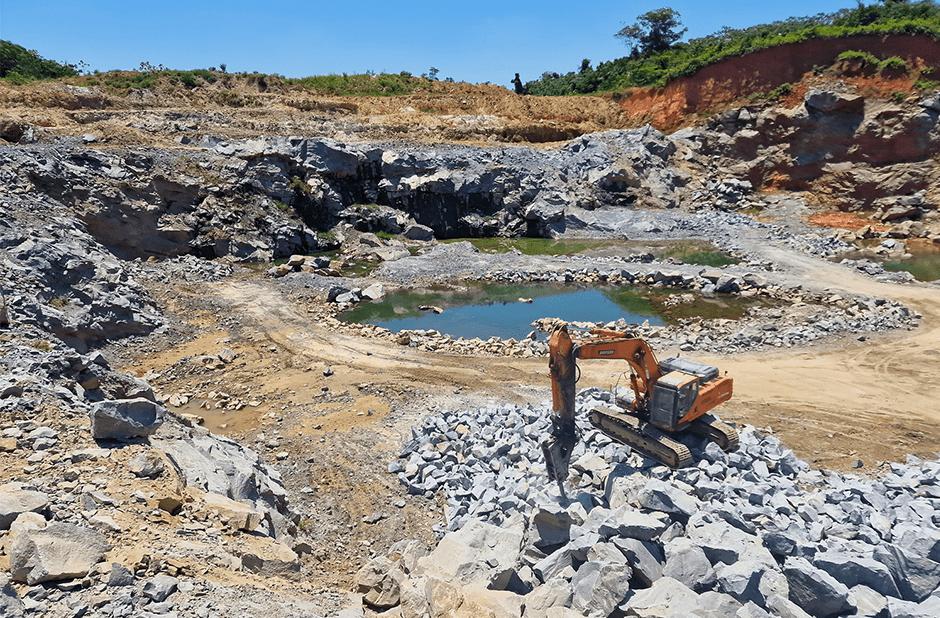

Full Size Weighbridge Civil Works

Step 1: Excavate, Shutter & Pour Concrete for Main Load Bearing Piers

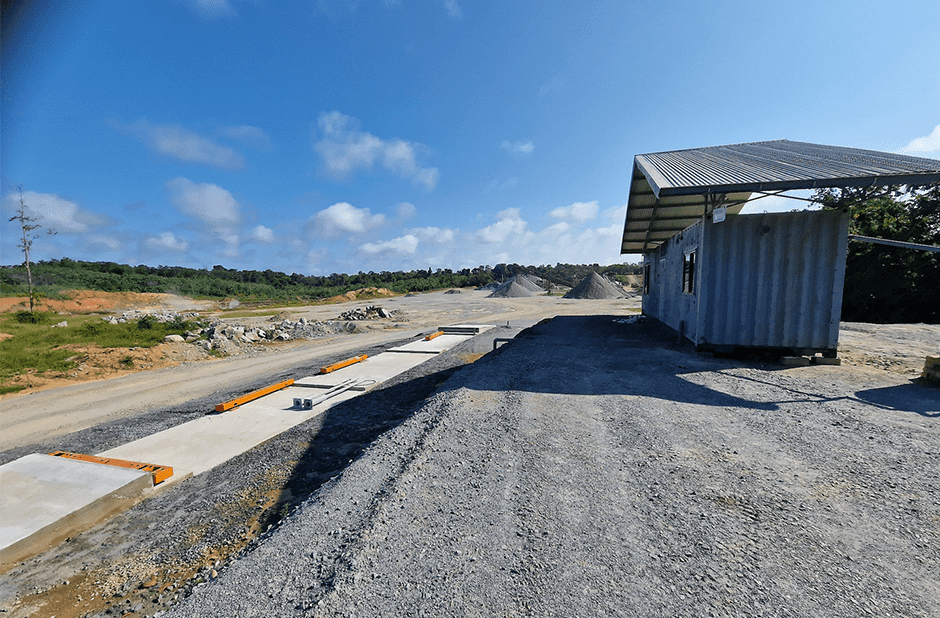

Our mining client purchased one of our Full Size Weighbridges, in which we assisted with the installation and civil works process. This Full-Size Weighbridge is 21.3 x 3.0m, 80-tonne capacity truck scale. This was being installed alongside our own Weighbus Software, remote fob button system for unmanned operation, large displays, traffic lights and cameras, all with dual-direction traffic flow over the weighbridge. This system is well-proven in numerous mines and quarries, overseas and in the UK.

Our Mining customer in Suriname, South America shared with us some pictures from the early stages of the process. Preparing the ground, including excavating, shuttering and pouring the concrete for the main load-bearing piers.

After civil works were completed our engineer travelled to Suriname to commission and train the operators and local engineers. This will ensure they are capable of utilising the truck scale to its’ full capability and can also self-maintain with our remote support over the long life of the product.

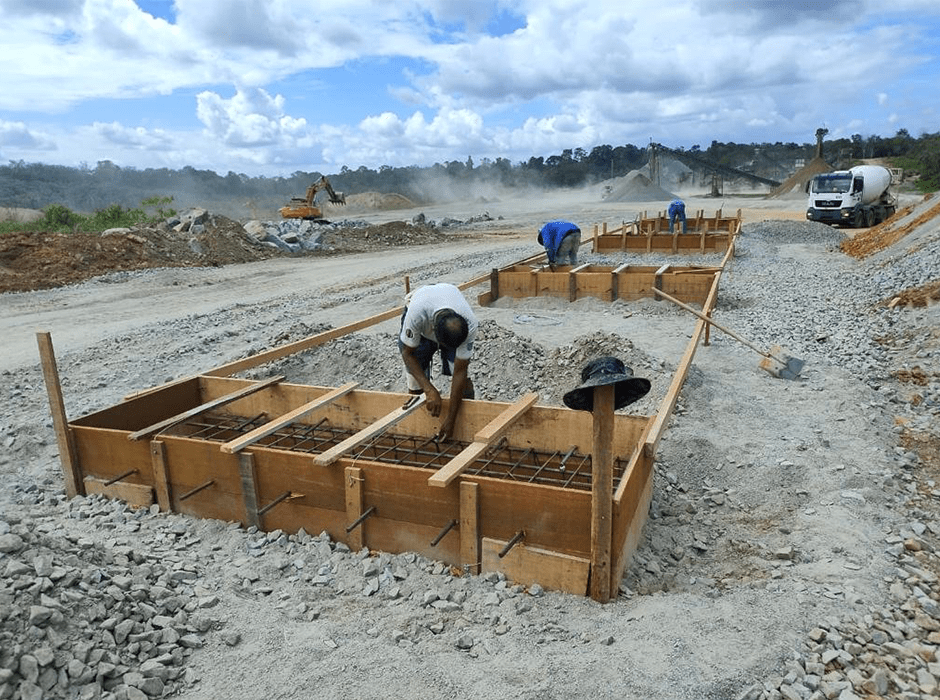

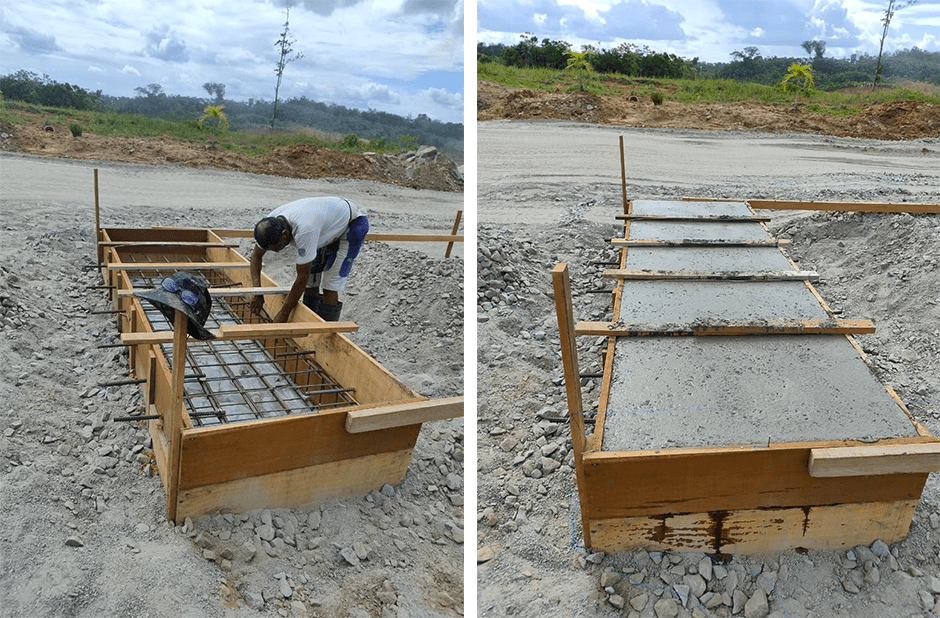

Full Size Weighbridge Civil Works

Step 2: Install Ducting, Shutter and Pour Concrete

The ducting was then installed for the signal cable to connect the weighbridge to the office equipment. In the below pictures, at both ends you can see the ducting ready for the posts that will mount the Weighbridge Large Display, Traffic Light, Cameras and RFID remote button FOB reader. This hardware gives the operator complete control and peace of mind during the weighing process.

The ramps and centre infill sections were also shuttered and poured. Infills are placed above the surrounding ground to minimise the flow of water as much as possible, and dirt ingress under the weighbridge.

The second set of weighbridge civil works photos shared by our mining customer in Suriname can be seen below.

Throughout the process, we remained in direct contact with the people on site. This included conducting the civil works and checking each stage before there could be any costly errors. This ensures a smooth installation, with correct and simple operation. This will also reduce and simplify future service work for our customers, which is especially important for our international customers.

Our dedicated support is why we have customers using our weighing equipment in over 50 countries across 6 continents. After the civil works was completed, our engineer prepared to travel to Suriname for the next stage in the installation work. Installing the weighbridge!

Full Size Weighbridge Installation

Step 3: Installation of Weighbridge, Large Displays, Traffic Lights, Cameras and FOB Readers

Our engineer Frank recently travelled to Suriname, South America, to install the weighbridge after civil works was complete. This was therefore the final stage of the project.

He was able to finish this in a few days and train our client’s operators and local engineers, and get everything up and running! Frank said about his experience,

“It was a pleasure to install the weighbridge for our customer and visit Suriname. They couldn’t have been more welcoming and helpful to me, and I could even experience the local food which was amazing!”

Steven Jungerman, CEO of Probandum Mining Company N.V. was pleased with the outcome, saying

“We were very grateful for the professional and kind assistance we encountered with Frank. Thank you so much for a great product.”

Our client is now able to self-maintain the weighbridge with our remote support. We additionally provide full support from beginning to end, both in country and remotely in the construction of our weighbridges. This makes it simple for our customers and offering peace of mind.

Get in touch with us today to find out how we can help you with your weighing requirements. Discover more information on our full selection of weighbridges.

Full Size Weighbridge, Installations, Quarries, Scales, Software, South America, Truck Scales