Portable Weighbridges: Benefits and Best Options

Portable weighbridges offer a practical solution for businesses aiming to enhance their operations. These efficient tools can cut operational costs by as much as 30% by streamlining vehicle loading and preventing overloading issues. From construction sites to agricultural fields, portable weighbridges provide the flexibility, accuracy, and efficiency that various industries need. Their ability to measure loads with precision makes them essential for compliance and operational excellence.

What You Need to Know:

- Flexibility in installation and relocation

- Cost-effective weighing solution

- Ensures compliance with weight regulations

- Improves operational efficiency

- Enhances safety by preventing overloading

Understanding Portable Weighbridges

Portable weighbridges can weigh vehicles up to 100 tonnes and generally measure between 2.5 to 3.5 meters wide. These versatile instruments are designed to be user-friendly while maintaining high precision and reliability. Griffith Elder’s portable weighbridges exemplify quality, extending their lifespan and ensuring dependable performance. They adapt like a chameleon, fitting seamlessly into diverse environments and demanding applications, offering businesses a reliable partner.

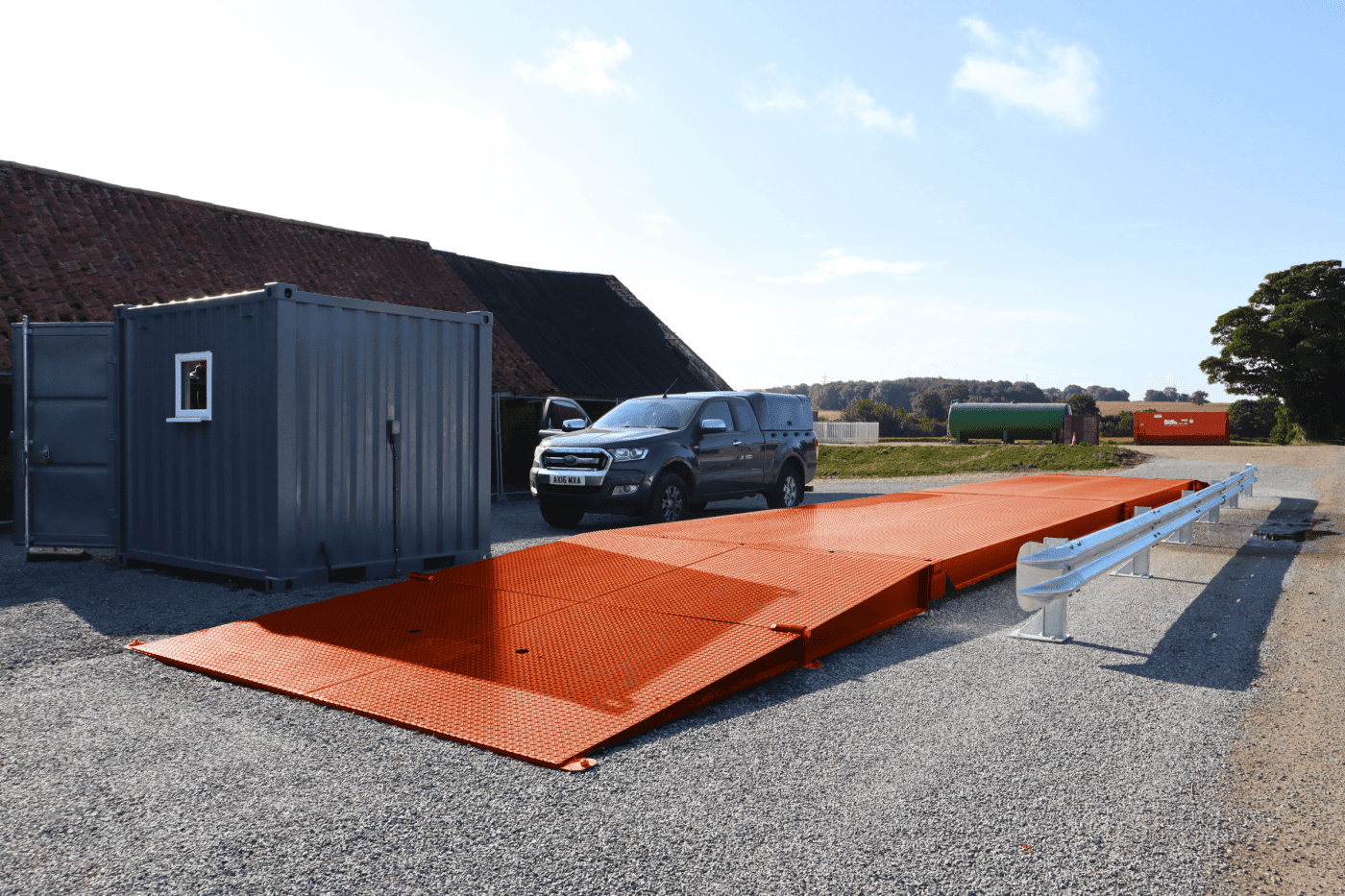

For those needing a full-size option, the Portable Full Size Weighbridge serves as an excellent choice. Alternatively, the Portable Single Axle Weighbridge suits lighter loads. Below are images showcasing these robust products.

Benefits of Portable Weighbridges

Portable weighbridges can cut weighing time by up to 50% compared to fixed installations. This efficiency translates to improved productivity and less downtime. Griffith Elder’s portable weighbridges eliminate the need for a prepared site, allowing for quick and hassle-free setup. Reducing wait time frees up resources to focus on what truly matters—growing your business.

With their user-friendly operation, these weighbridges enhance compliance with weight regulations, helping businesses avoid the costly penalties tied to overloading.

Types of Portable Weighbridges

Single axle portable weighbridges can typically handle loads of up to 20 tonnes per axle, making them great for lighter vehicles. Griffith Elder provides a variety of options, including both single axle and full-size models to cater to diverse needs. This flexibility enables businesses to choose the right weighbridge for their specific operations. Think of it as a custom-tailored suit, designed to fit the unique requirements of your business.

Whether it’s a full-size option for heavier loads or a compact single axle model for lighter applications, Griffith Elder’s offerings ensure that businesses can find the ideal fit.

Griffith Elder’s Portable Single Axle Weighbridge

Weighing only 300kg, the Griffith Elder Portable Single Axle Weighbridge is easy to lift with a forklift. Measuring 2.5 meters wide, this weighbridge can accommodate loads of up to 20 tonnes per axle, making it a strong solution for various applications. This portable option is practical in an industry where weight management is vital. Designed for convenience, this weighbridge sets up quickly without requiring extensive groundwork.

Griffith Elder’s Portable Full Size Weighbridge

Griffith Elder’s full-size portable weighbridges vary from 4 to 32 meters in length, catering to a wide range of applications. These weighbridges come in widths of 3.0, 3.5, and 4.0 meters, addressing the diverse needs of various industries. With such versatility, these weighbridges are like a Swiss Army knife of weighing solutions, prepared to tackle any logistical challenge. Designed for high precision and durability, these weighbridges suit businesses that need versatile and reliable weighing solutions.

Weigh Beams: A Flexible Alternative to Traditional Portable Weighbridges

Weigh beams represent an innovative and adaptable solution for businesses seeking efficient weighing capabilities without the commitment to a full-size portable weighbridge. These versatile components utilize advanced load cell technology to convert force into precise weight measurements, offering the same level of accuracy while maintaining a significantly smaller footprint. With their compact design and ease of transportation, weigh beams can be quickly deployed in various locations, making them an ideal choice for operations that require frequent mobility and flexibility in their weighing solutions.

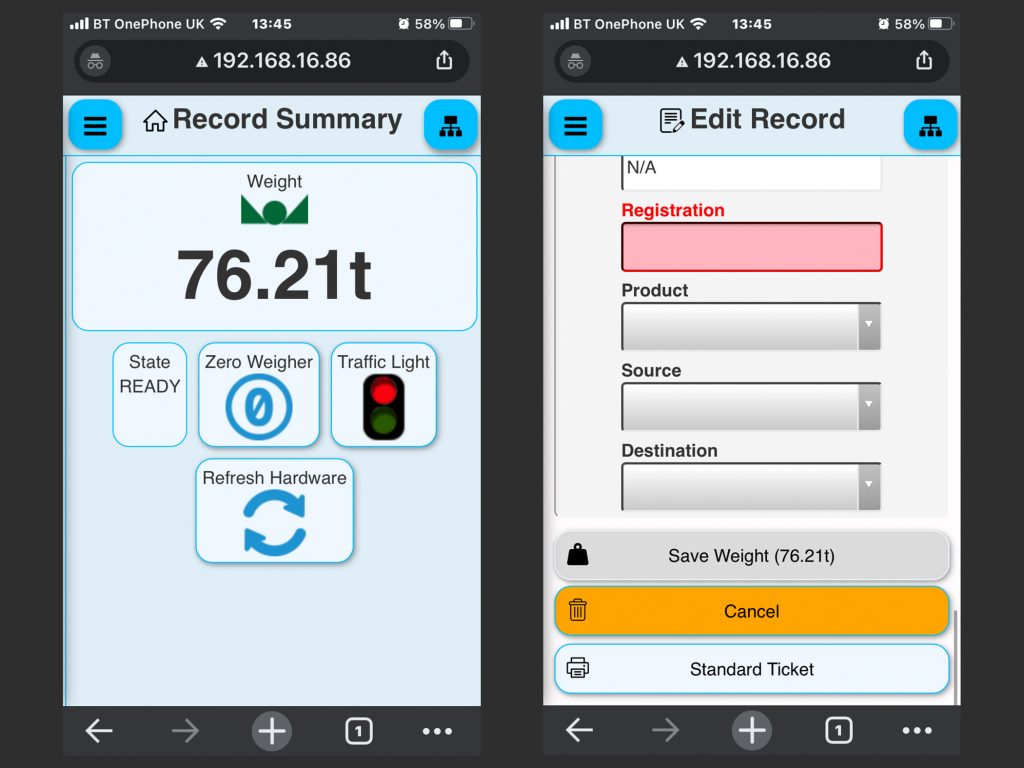

Like their full-size counterparts, weigh beam systems can be seamlessly integrated with modern weighing software such as the Ton-Telâ„¢ system, providing comprehensive data management capabilities. Their ability to handle precise measurements while requiring minimal setup time and no prepared site makes them particularly attractive for agricultural operations, construction sites, and other industries where rapid deployment and reliable weighing capabilities are essential for maintaining operational efficiency.

Choosing the Right Portable Weighbridge

The cost of a portable weighbridge ranges from approximately £12,000 to £25,000, depending on specific requirements and complexities. Griffith Elder offers customized solutions that allow businesses to match the weighbridge capacity to their needs, ensuring optimal performance. Selecting the right weighbridge can significantly impact operational success, much like choosing the right tool for a job. By evaluating intended applications and load requirements, businesses can make informed decisions.

Installation and Setup of Portable Weighbridges

Proper installation is crucial, as it can increase a weighbridge’s accuracy by up to 99.9%. Griffith Elder’s portable weighbridges are designed for quick and easy setup, requiring no prepared site. This feature significantly reduces downtime and allows for immediate use. Imagine starting operations the moment you arrive, eliminating the wait time that often stalls productivity. Businesses benefit from the swift installation process, ensuring operations run smoothly and efficiently.

Maintenance and Calibration

Regular calibration can extend the lifespan of a weighbridge by up to 25%. Griffith Elder emphasizes the importance of proper maintenance to ensure longevity and reliability. Scheduled checks and routine calibration help maintain the accuracy and effectiveness of the weighbridge. Think of it as a car needing regular oil changes; diligent maintenance ensures smooth operation. By adhering to a maintenance schedule, businesses can ensure their weighing solutions continue functioning optimally.

Integration with Weighing Software

Integrated weighing software can improve operational efficiency by up to 40%. Griffith Elder’s weighbridges can seamlessly integrate with their Ton-Tel™ electronics, offering comprehensive weight management solutions. This integration allows businesses to streamline operations and gain valuable insights from weighing data. In today’s world, having real-time access to weight metrics can be a game-changer. By leveraging technology, companies can significantly enhance their operational capabilities.

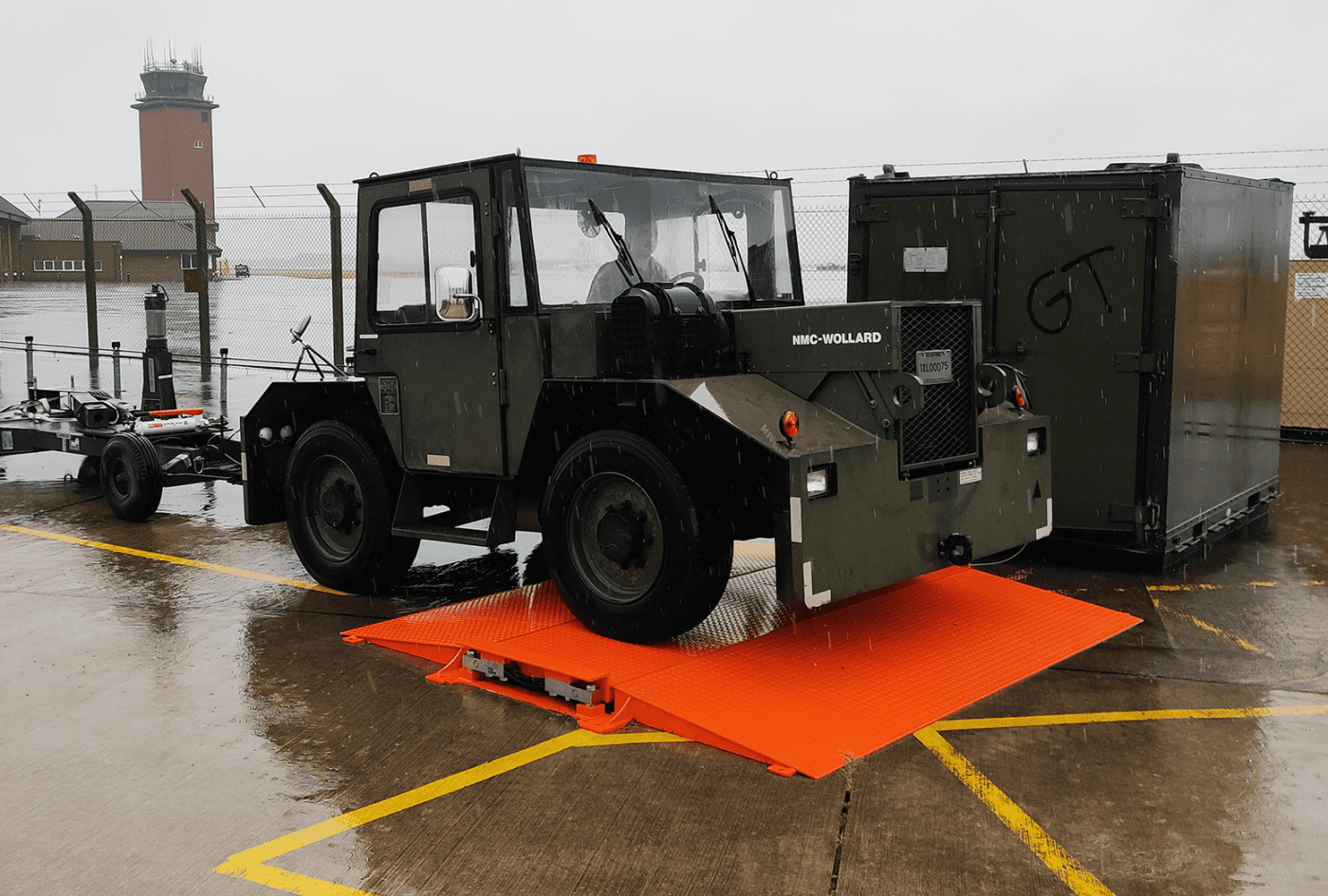

Case Studies: Successful Implementations

Companies using portable weighbridges report an average 20% increase in operational efficiency. Griffith Elder has successfully implemented weighbridge solutions across various industries, including construction and mining. These case studies provide valuable insights into how portable weighbridges can positively impact business operations. Analyzing real-world applications can illuminate the path forward for businesses contemplating their own weighbridge journey.

By studying these implementations, businesses can better understand the potential benefits of integrating weighbridge solutions into their operations. Below are images from successful implementations.

Conclusion: Making the Right Choice for Your Business

Proper selection and implementation of a portable weighbridge can yield a return on investment within 12-18 months. Griffith Elder offers a wide range of portable weighbridge solutions tailored to meet diverse industry needs. By choosing the right solutions, businesses can boost their operational efficiency while ensuring compliance and safety. The right weighbridge is not just a purchase; it’s a strategic investment in the future of your operations.

FAQ Section

1. What are the main benefits of using a portable weighbridge?

Portable weighbridges provide flexibility, cost-effectiveness, compliance with weight regulations, improved operational efficiency, and enhanced safety by preventing overloading.

2. How do I choose between a single axle and full-size portable weighbridge?

Consider your specific load requirements and the types of vehicles you will be weighing. Single axle weighbridges are suitable for lighter vehicles, while full-size options cater to heavier loads.

3. What maintenance is required for a portable weighbridge?

Regular calibration and maintenance checks are essential to ensure accuracy and prolong the lifespan of the weighbridge.

4. Can portable weighbridges integrate with existing management systems?

Yes, Griffith Elder’s portable weighbridges can be integrated with their Ton-Tel™ electronics for comprehensive weight management solutions.

5. How accurate are Griffith Elder’s portable weighbridges?

With proper installation and calibration, Griffith Elder’s portable weighbridges can achieve accuracy levels of up to 99.9%.

Key Points

- Portable weighbridges can save up to 30% in operational costs.

- They can weigh vehicles up to 100 tonnes with high precision.

- Setup is quick and does not require extensive groundwork.

- Regular maintenance can extend the lifespan by up to 25%.